Case Study: Optimizing a Quality Management System (QMS)

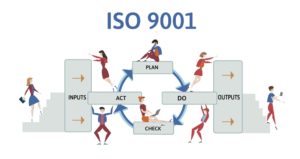

One of Prosit’s regular clients needed more assistance involving their Quality Management System (QMS). There were documents that were outdated, references incorrect, job descriptions were too vague, and employees listed that were no longer with the company.

One of Prosit’s regular clients needed more assistance involving their Quality Management System (QMS). There were documents that were outdated, references incorrect, job descriptions were too vague, and employees listed that were no longer with the company.

Prosit gathered a team together with seven employees. The QMS was brought up and a list of priorities was created to get a grasp on what to tackle. One by one, the team went down the list creating flow charts where they were missing, updated employee information records, and validated processes that were being done versus what the process forms were stating.

If anything needed to be changed it was attacked and action items were created. The team met on a weekly basis for two months. This was all in preparation for an internal and external audit that was to be conducted in 2020.

Current status, this company now has validated most of their documents and effectively cleaned up the QMS system. However, this has created more action items and areas to be improved which Prosit is actively working on with the team. In the near future, the system will fully reflect what is being done on the shop floor accurately.

Additionally, the improvement team will use these learned skills to conduct more events similar to this one, if the need arises.

Please contact Prosit to see how we can assist your company with your lean enterprise and consulting needs.