Lean Enterprise Overview

Transforming an Enterprise, Organization, Division, Department or Operation requires more than just tools, it requires VISION, HARD WORK, EXPERTISE, and EXPERIENCE, in creating or transforming processes into Lean, Efficient, Customer-Based processes that support business strategy and positively affect the bottom line. Knowledge of the Lean Tools is important, but a strategy to deploy them, and partnering with those who have mastered that is critical.

What is your Strategy?

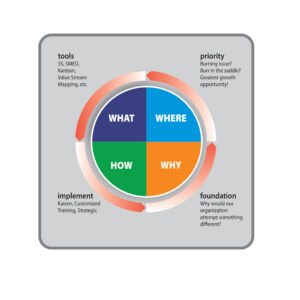

We believe strongly in identifying the fundamental opportunities for improvement and facilitating that discovery assessment by using the proven process of asking Why, Where, What and How?

Why

Why uncovers the reasons the company wants to change, improve and what goals need to be achieved. Strategy is essential to executing a successful plan. It is critical if you want to achieve meaningful goals. While some organizations get mesmerized by the tools and techniques, they frequently ignore the fundamental step of developing and sharing their vision of what they want the Lean Enterprise effort to deliver. It isn’t enough to master the techniques; we need to be able to communicate effectively within the organization. That way everyone can contribute and traction and progress can be achieved. Prosit Leads with strategy, and can help you develop a clear vision for your teams to follow and even expand.

Ask:

- “Why would our organization attempt something different?”

- What do you want to accomplish?

- What problems are you facing now that you need to deal with immediately?

- What achievements would you like to experience?

Where

Where identifies the priority areas for improvement and where the most value could be gained. Lean only works on the shop floor? Guess again. Lean Enterprise means the entire Order to Cash cycle, including the Supply Chain, can reap benefits from Lean Methodology. Often overlooked, Lean Office means reduced days AR, shorter Monthly Close and improved visibility and communication throughout the office. Naturally, the application of Lean Manufacturing on the shop floor remains valid to yield tremendous results in velocity of product towards a Lean Enterprise.

Operations: Plant Floor, Shipping, Receiving, Materials Management, Production Management

Administrative: Finance, Purchasing, Human Resources, Payroll, Sales, Customer Service

What

What focuses on the tools necessary to accomplish the goals of the company while also fitting the priority area’s unique requirements. We work together to customize a solution or implementation plan that fits with your immediate goals, budget and resources. Assessment through Value Stream Mapping typically offers the greatest insight into organizational challenges and opportunities with real and current information.

- Value Stream Mapping – An assessment workshop designed to create maps of the Current State, a Future State, and Implementation Plan

- 5S – Workplace Organization and Visual Factory techniques to make the factory “talk” to us. Are we On Time, Late, Safe? Do we have enough Inventory or Too Much? Am I staffed correctly? Do my associates know what to do next and how to do it?

- Lean Office – Opportunity to drastically improve flow of information and productivity

- SMED – Single Minute Exchange of Dies, or Quick Change-over. “Everybody is already working hard. I don’t think we can shorten our setup times.”

- A3 – PDCA Improvement process – Methodical planning and follow through to ensure success

- Cellular Flow – Next Level approach to optimizing flow of material and/or information for a process or production part. Reduces space, Inventory requirements, lead times and defects.

- Pull Systems/Kanban – Trigger replenishment, purchase or production at the pull of customer demand. Using simple systems or thin layers of technology to communicate consumption rather than forecasts which are often just guesses.

How

How deals with implementing these improvement changes, how employees, managers, executives are trained, how to secure adoption within the company and ensure long term adhesion to the new direction. Properly implemented tools of Lean yield powerful results.

However… knowing what to do, is not the same thing as knowing how to do it.

This is where your consulting choice is critical. Academic knowledge or experience with the tools is not enough. There are thousands of outlets for Lean Tools. You want to trust your organization with consultants that not only have true command of the tools, but have successfully navigated the challenges of Culture, History, Negativity, and other Organizational difficulties and can facilitate real impact and lasting change.

Activity Based on Strategy

- Address Culture, Teams, Training and Awareness, Create Champions

- Kaizen Methodology, Project Management, Systematize and Standardize the Lean effort

- Establish Metrics to Manage the Change Process

- Leadership Team development

- Sustain Coaching

Any direction just isn’t good enough. Resources are precious, and so are the victories from the Lean journey. “That which you measure improves.” You have made a good decision to pursue Lean Enterprise. Now make a great decision in your consulting partner.

Please contact us for any of your lean enterprise needs in the Philadelphia, PA region or across the country.