Case Study: The Value of Lean Continuous Improvement

A long term client of Prosit recently approached them for help addressing two specific problems.

First, no set process had been developed for scheduling their paint department efficiently. As their product moved through each department in the factory, they found the product 80% of the time, flowed into the paint department staging area with no warning from the upstream customer.

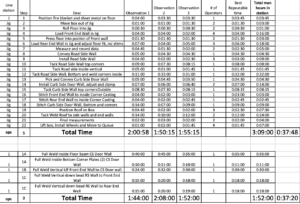

Prosit worked very closely with the client to perform time studies that produced accurate time frame data for jobs in the paint department and in the fabrication department upstream. This data allowed Prosit to create a detailed department schedule the supervisor and plant manager agreed upon and could use with minimal changes. Building this schedule also helped the client understand the actual work content involved in complicated jobs; information that was not known before this process.

The second was defective or incorrect vendor supplied material was not being tracked and consequently chargeback invoices began to fade out.

Prosit again worked with the client closely to establish a tracking process for any material that needed modification from the client’s vendors. The process included input from project managers, supervisors, material handling teams, and plant managers. The tracked defective or incorrect material data was documented in a spreadsheet so the owner of each possible chargeback was informed and prepared to confirm the transaction was made.

Due to this work, the client has a stronger vendor relation through the chargeback process. The process identified action steps to evaluate vendors that were either unresponsive or consistently sub par at delivering the correct material. The client realized a savings of $40,000 which made them very happy.

Please contact Prosit to see how we can help your company too.